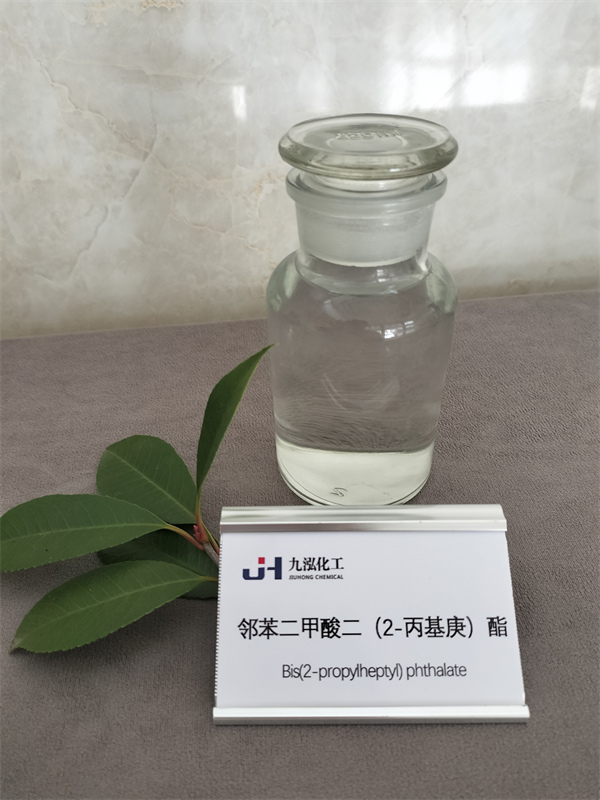

C28H46O4 DPHP Plasticizer

CAS:53306-54-0

Formula: C28H46O4

Purity: 99.5%

Di (2-propylheptyl) phthalate can withstand higher temperatures and is more safety. DPHP can be used alone, or in combination with other plasticizers. Widely used in the production of plastic and rubber, it is an excellent plasticizer product in phthalate esters.

C28H46O4 DPHP plasticizer

About the Parameter

Technical Standard HG/T 4889-2016

Index name | Index | |

Superior products | First-grade products | |

Appearance | Transparent oily liquid without visible impurities | |

Chroma, (Pt Co) No≤ | 25 | 40 |

Purity (GC),% ≥ | 99.5 | 99.0 |

Flash point (open cup method), ℃ ≥ | 210 | 205 |

Acid value, mgKOH/g ≤ | 0.07 | 0.1 |

Density(ρ20),g/cm3 | 0.957~0.965 | |

Moisture,% ≤ | 0.10 | 0.15 |

Volume resistivity(1010Ω·m)≥ | 10 | 5 |

Product Performance and Application

Di (2-propylheptyl) phthalate, short as DPHP, has a molecular formula of C28H46O4 and a relative molecular weight of 446.7. It is colorless, transparent, viscous, oily liquid with slight odor, low toxicity, low volatility, high stability, and soluble in most organic solvents.

Di (2-propylheptyl) phthalate has good compatibility with PVC, and its plasticizing efficiency is superior to DOTP. In addition, the electrical insulation performance is the same as DOTP, but the volatility is less. It can withstand higher temperatures and is more safety. DPHP can be used alone, or in combination with other plasticizers, or instead of DBP, DINP, BBP and other plasticizers. Widely used in the production of plastic and rubber, it is an excellent plasticizer product in phthalate esters.

About the Package

We can do the delivery as soon as we receive the full payment, according to your requirement.

Tere are 4 kinds of packages available:

1. 200kg Iron drums

2. 1000kg IBC drums

3. 23mt Flexibag

4. 24.8mt ISO TANK

About the Production Device

The plasticizer device of Jiuhong chemical has been upgraded, on the basis of summary and absorption of the advanced technology from foreign country.And we has obtained 18 utility model patent certificates successively.

The advantages are as follow:

Advanced technology: the new production equipment, more efficient, cost saving.

Environmental protection and safety,using incineration alkali washing process, setting exhaust absorption device to prevent organic emission.

Design and control equipment is unique, they are safe on operation to achieve the optimal production of the device.

Efficient process method, energy self-sufficiency. The plasticizer production process is a heat absorption process, that is, the steam required by the device in the production is provided by the benzene crisp device.

Adopt the waterless process to reduce the process sewage discharge and meet the environmental protection requirements

FAQ

Q1: Are you the trading company or manufacturer ?

A: We are the manufacturer.

Q2: Can I get a free sample?

A: Yes, a sample less than 2 kg is free, you only need to pay the delivery cost.

Q3. What is your terms of payment?

A:We prefer TT, 30% as deposit, and 70% before delivery. but other ways is also negotiable.

Q4: How long is your delivery time?

A: We can do the delivery as soon as the payment.

Q5. Do you test all your goods before delivery?

A: Yes, we will test the product at least 3 times during the producing, And before delivery we will test it again.